Modern standing seam roofing consists of several details. Some of them can be applied in other kinds of roofing for example: roofing tile coatings and some are specific only for standing seam roofing and are not applied in any other roofing.

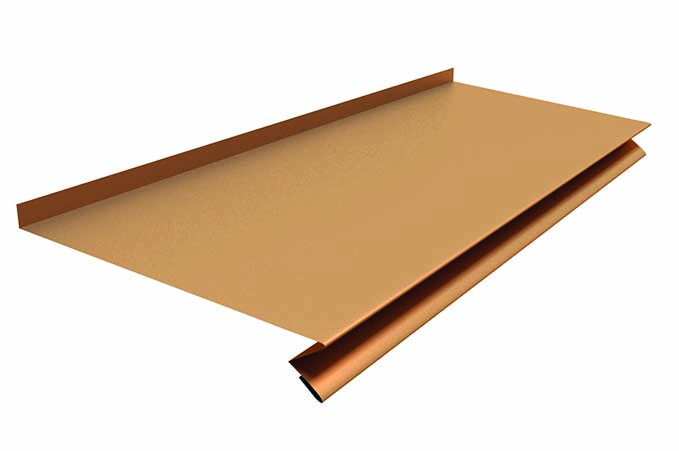

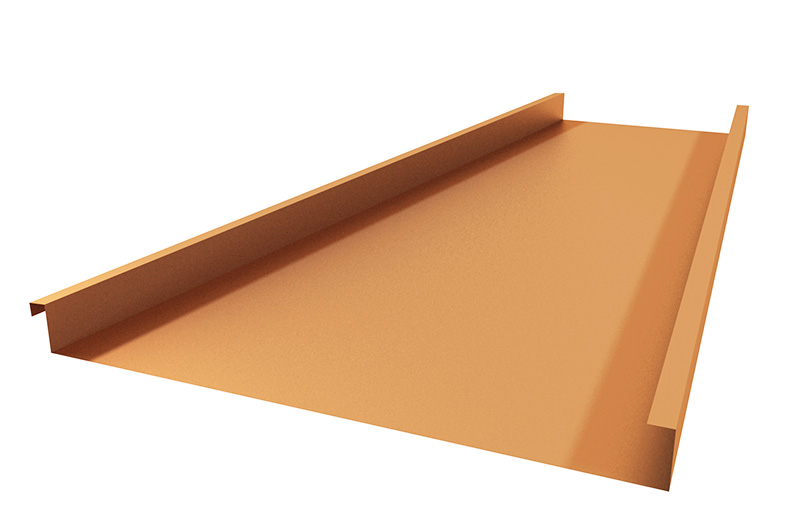

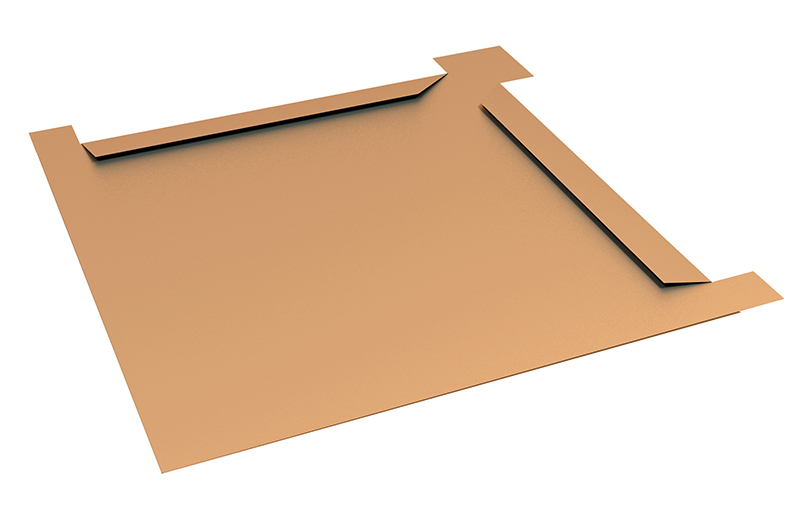

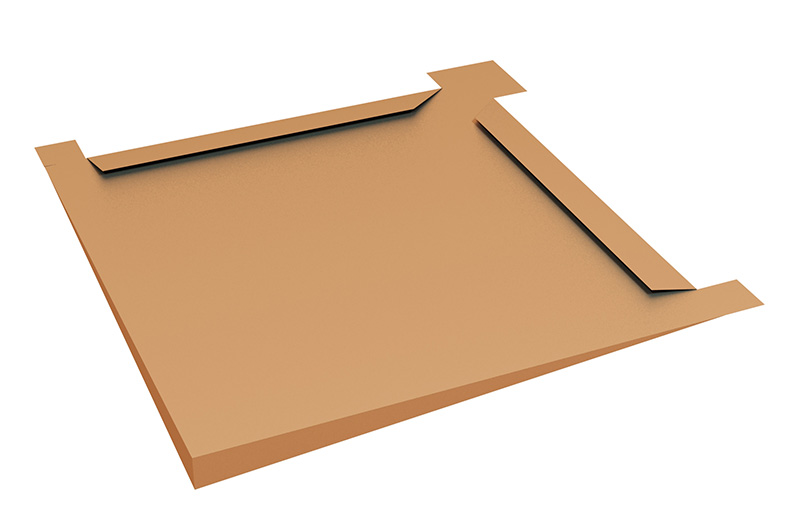

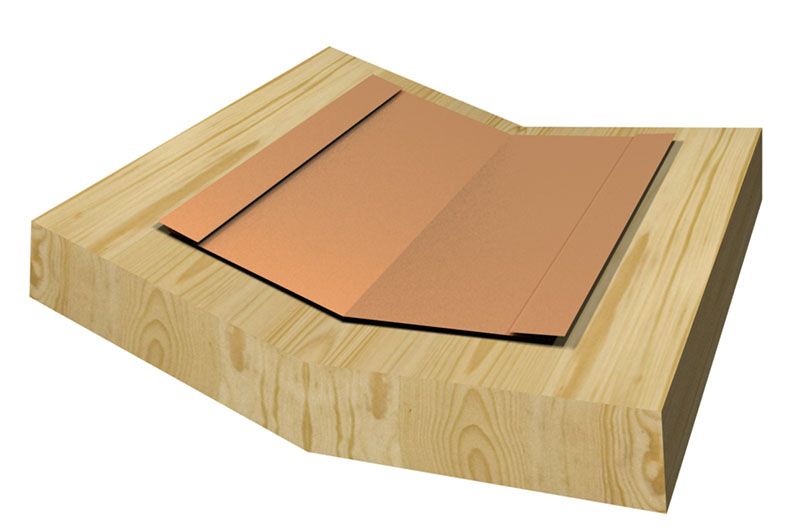

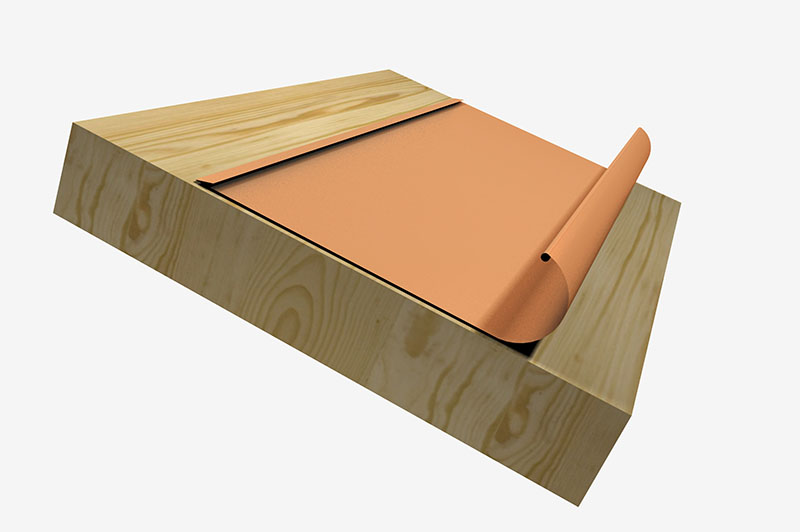

All elements are fabricated in our production area on our seam-rolling and bending machines made in Ukraine, Germany, France and USA as well as machines made by ourselves. Roofing sheet is the most frequently used element of standing seam roofing. It is used for in-line coating of the main area of roofing. The width of sheet can be of any size however the most frequently used sheet width is 1/2 or 1/3 of coil width (0,5m and 0,3m correspondingly). The coil is cut into strips on special machine for longitudinal metal cutting. Received blank strips are rolled on standing seam rolling machine to get lateral seam locks for the sheets. Then the seams are rolled up with the help of special tool or electro mechanic seam-rolling machines.

Standing seam panel, roofing tile of various sizes and kinds are the main elements for in-line covering of slopes.

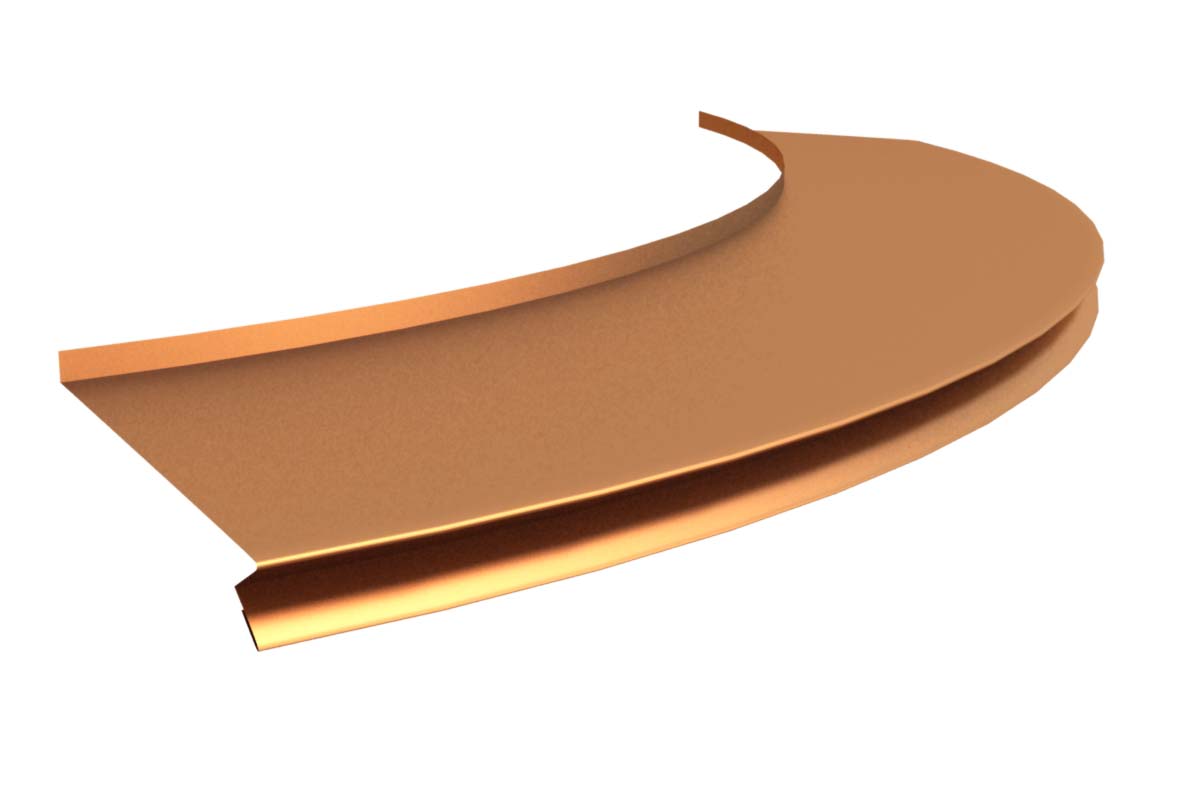

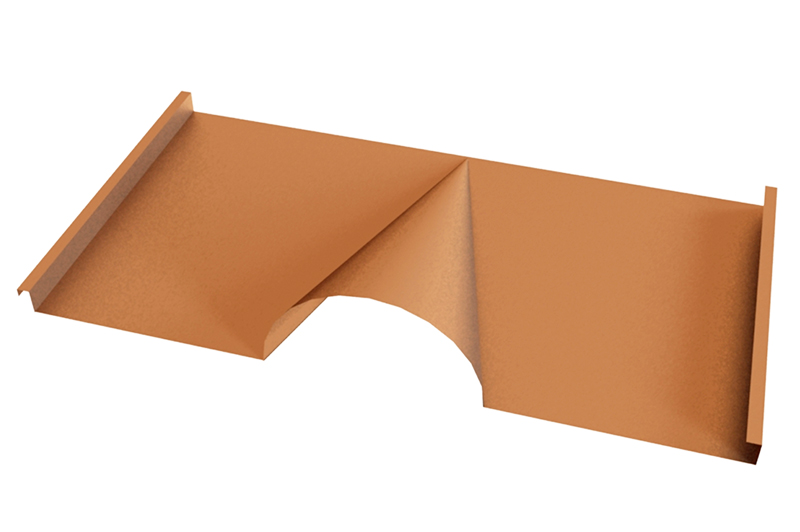

To perform back gutter on slopes joints valleys are used. They are two kinds of valleys, i.e. straight and bended. Technology of bent valley fabrication for circuit abutment windows and to perform back gutter of curved slopes is our own invention. Only our specialists are able to fabricate such valley using special equipment. Special feature of curved valley fabrication in our company is the absence of locks and joints seams. Valley is executed all-in-one-piece which excludes the possibility of its leaking.

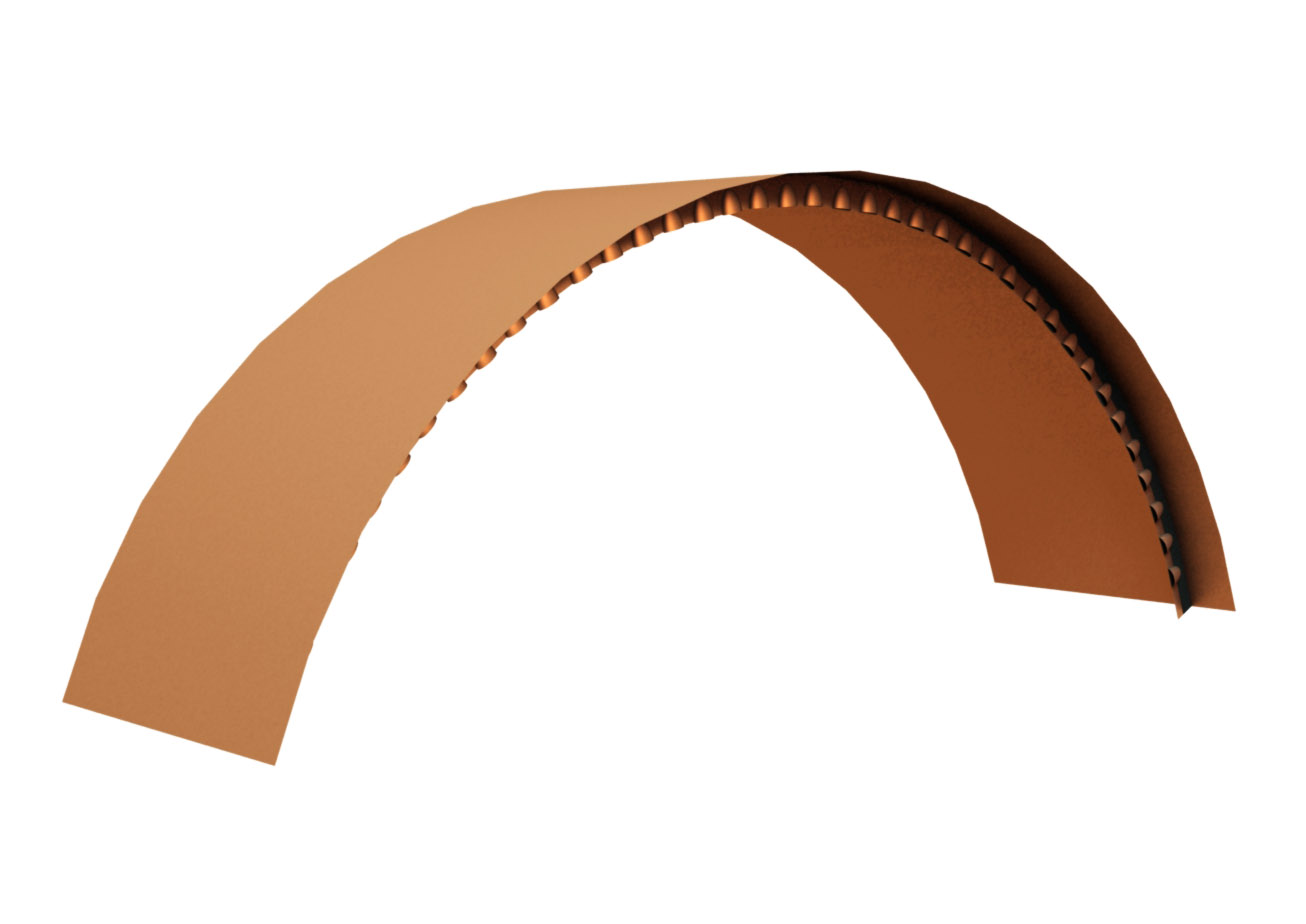

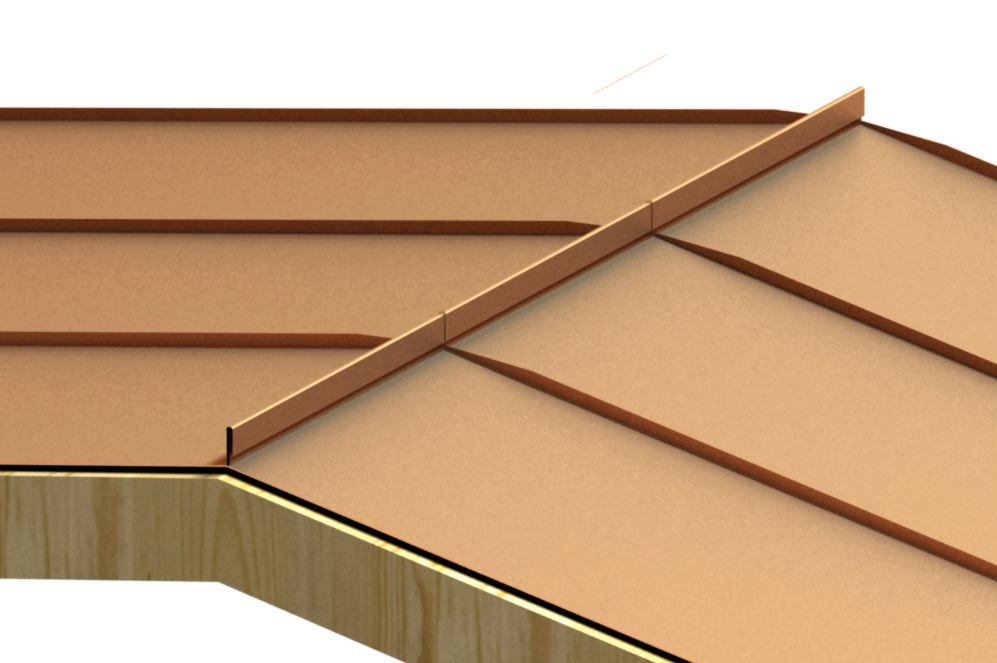

Standing seam roofing ridge is executed using several methods. The most frequently used method is ridge fastening with rivets to single or double-seam lock. This method is used both for standing seam panels and roofing tile covering. There is also another kind of ridge i.e. ventilated ridge or in other words solid ridge which provides roofing ventilation.

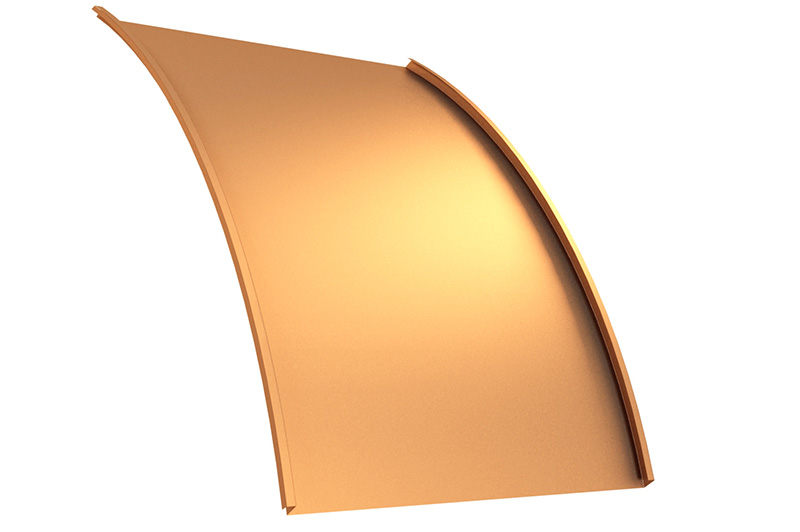

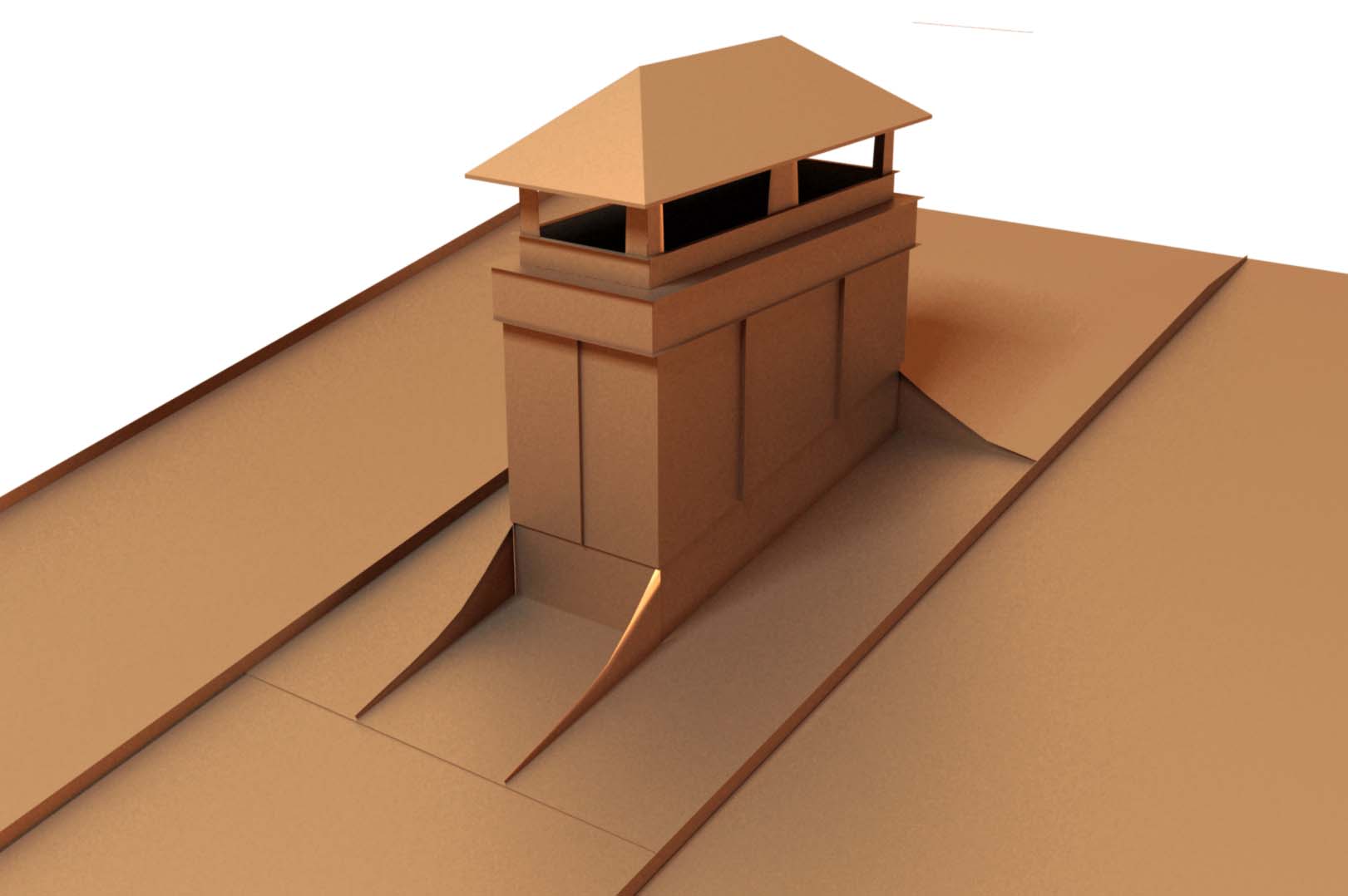

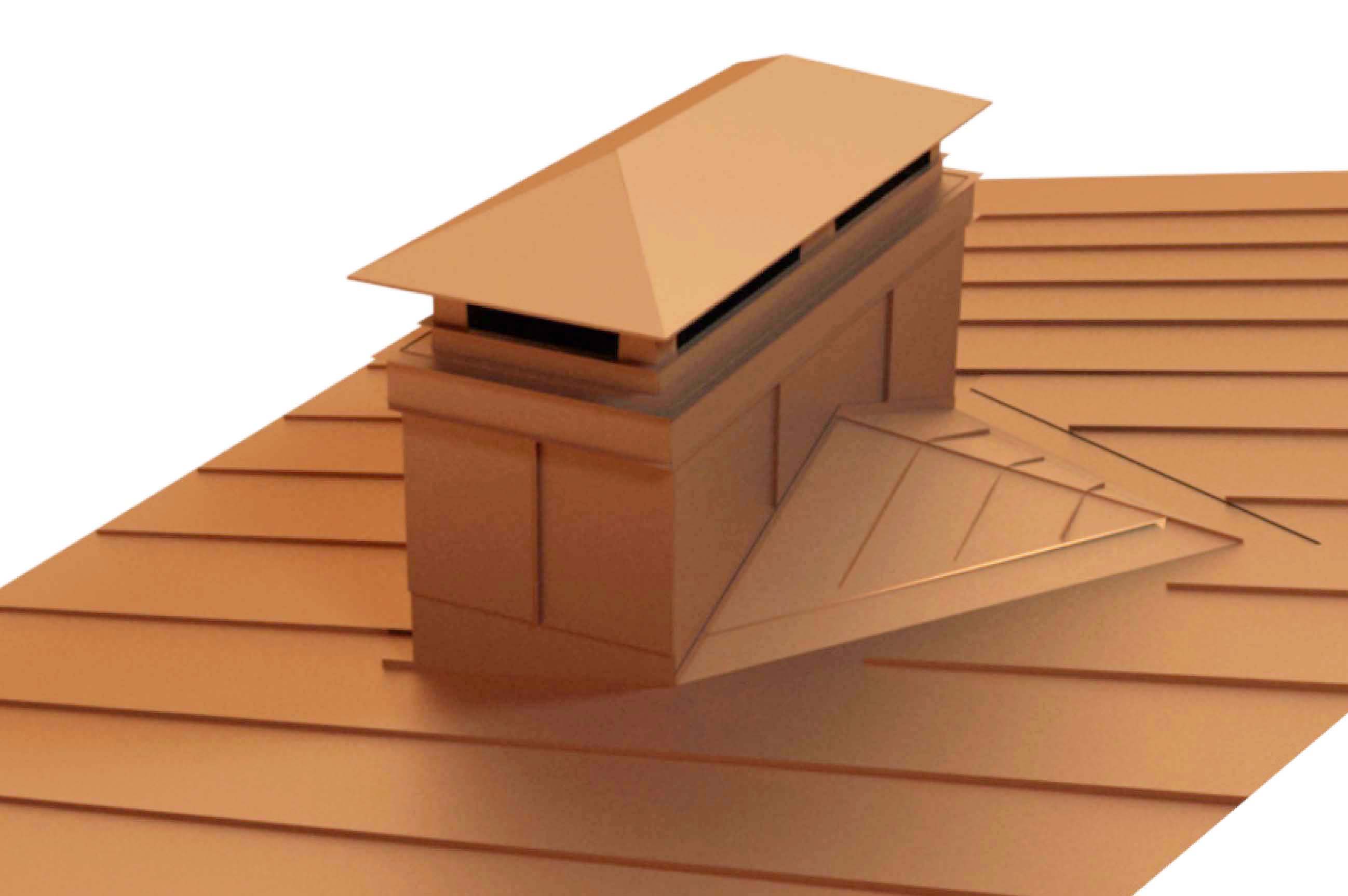

Great attention is paid to chimney flue, ventilation ducts, mansard dormer windows and etc. abutment while applying standing seam technology. For this purpose abutments are applied. All of them are installed using the principle of water withdrawal from problem points and exclusion of snow pockets. Chimney flue abutment is part of standing seam roofing. It is harmonically complied with the roofing and serves as roofing protection from leakages. There are abutments of different shapes and dimensions and can be applied both to round pipes (for example, sewage pipes) and rectangular-shape ventilation ducts. Cowls of different shapes are used to impart shape perfection to chimney flue or ventilation duct as well to protect chimney flue from atmospheric precipitations impacts.

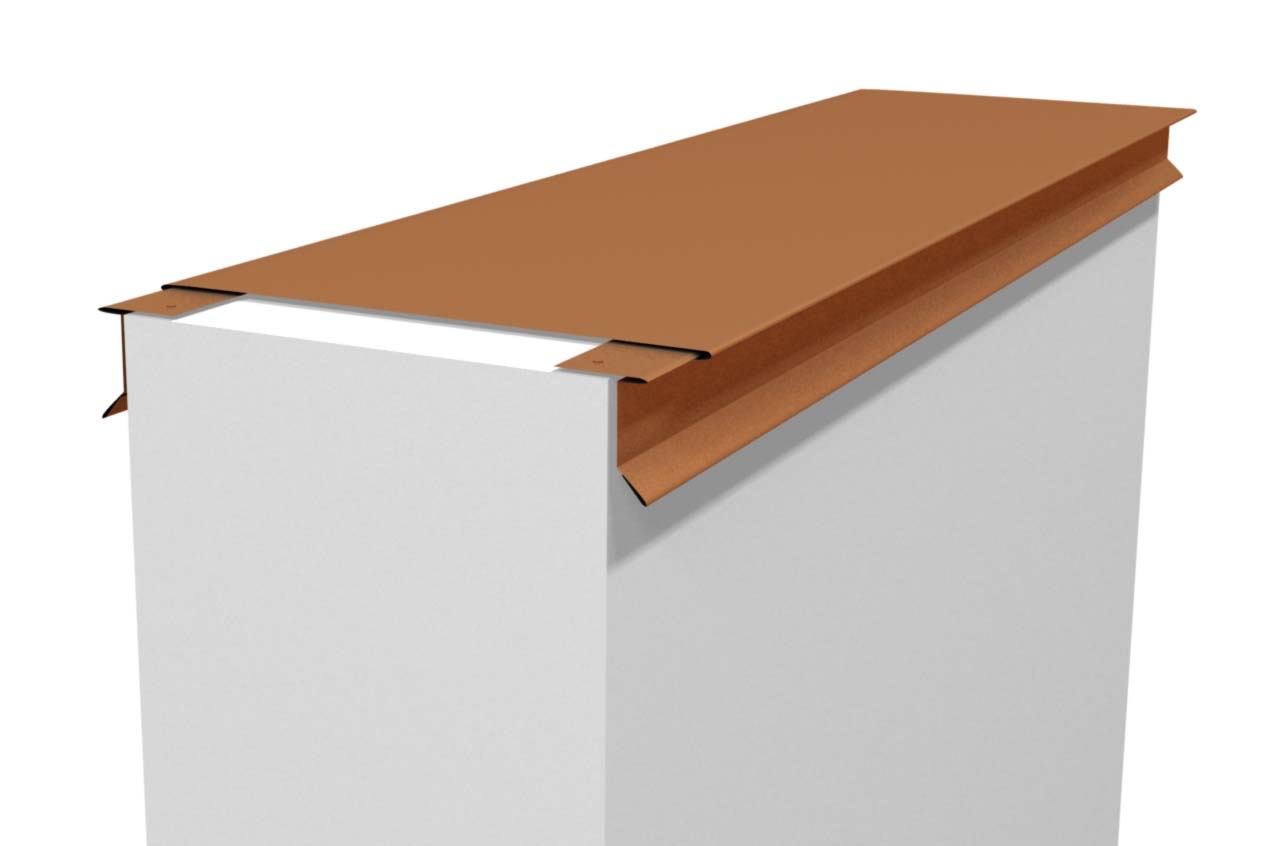

Standing seam roofing is not finalized by installation seam panels or roofing tile only. With the help of seam locks it is possible to finely and reliably protect roofing ends, parapets, and make long-life abutment to wall. No screws and “overlapped” assembly! Everything is done with the help of seam locks and hidden fittings. We don’t use standard details. We fabricate an individual ledge locally which allows to accurate and economic consumption of materials.

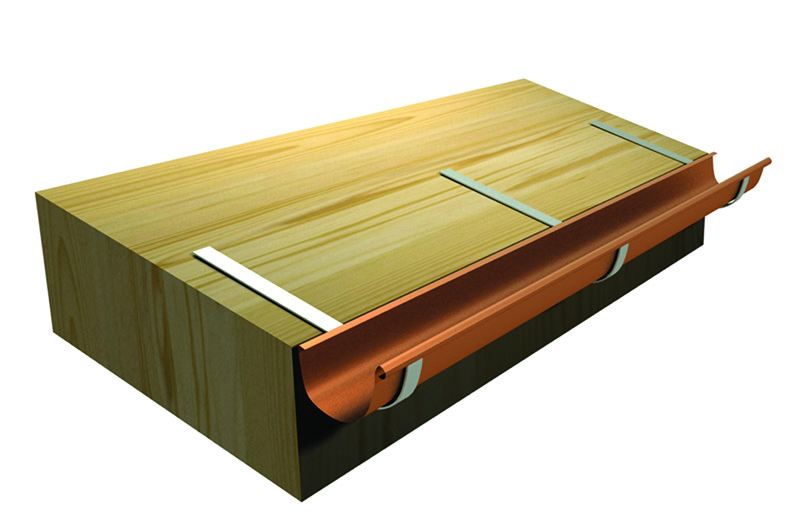

Any standard gutter system will fit standing seam roofing water drains arrangement. But other solutions are also used for standing seam roofing. One of them is standard cut-in (or classical standing seam) gutter which ensures not only water withdrawal but the effective snow retention. Suspended gutter is also frequently used which is mounted either to substructure or butt-end board which is arranged under cantilever.

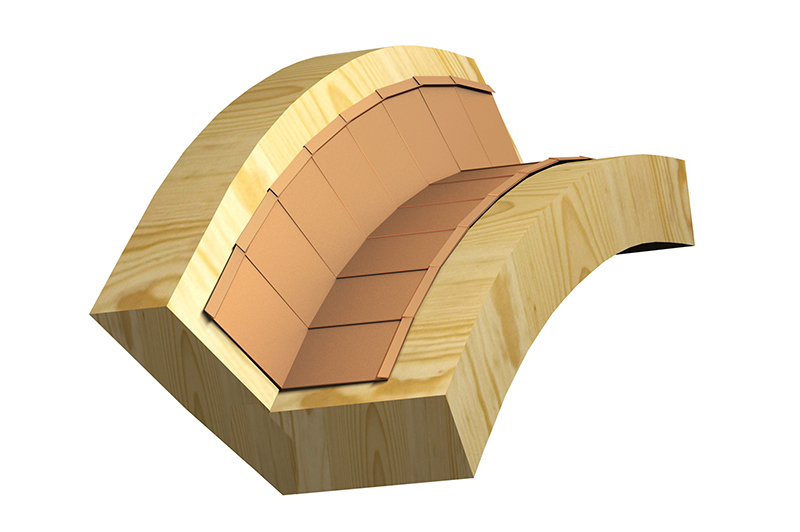

In case there are decorative eaves on the façade or there is a necessity to make water gutter low-visible the hidden gutter is used which can be made both with exterior funnels and hidden funnels. Sometimes it is necessary to make curved gutter or radius one. Hidden gutter can be radius-bended or arched which is not possible while using standard gutter system.

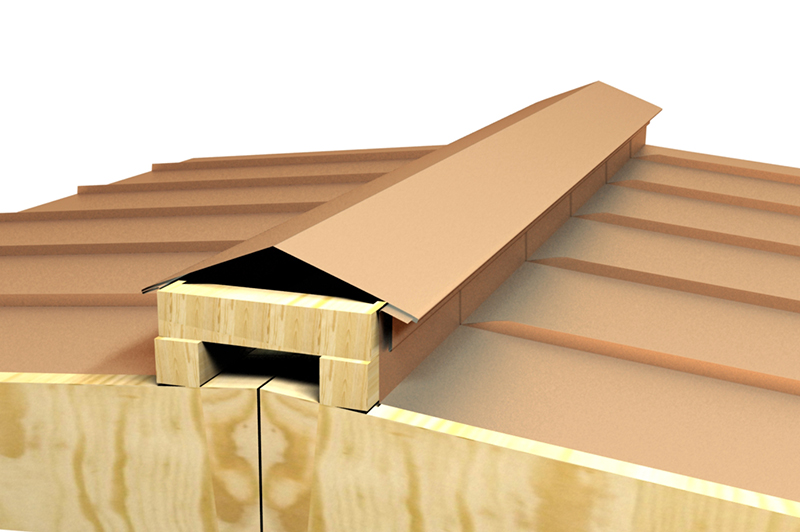

Effective service of mansard roofing is impossible without good ventilation. Various design aerators are used for standing seam and roofing tile roofs. The main function of aerator is air withdrawal from sub roofing ventilation. Aerators are cut in roofing and secured by hidden fittings without roofing perforation.

Besides roofing it is often necessary to install metal flashings on façade décor, windows flashings, balcony flashings and etc. This is the continuation of the general concept of standing seam roofing.